Stephan Balkenhol Teddybaer neue Bronze | FRANK FLUEGEL GALERIE - Ausstellung Nuernberg

Ausstellung Galerie FRANK FLUEGEL GALERIE

Datum: 28.03.2025 - 31.12.2025

Künstler: Stephan Balkenhol

Veranstalter & Ort:

Galerie FRANK FLUEGEL GALERIE

90403 Nuernberg

Obere Woerthstr. 12

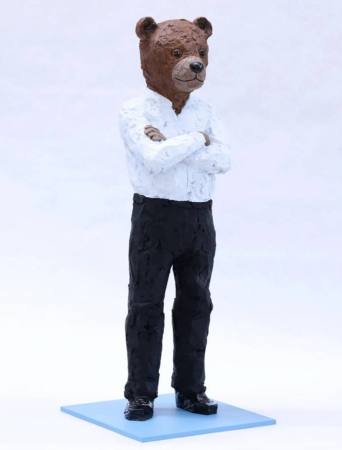

New Bronze Sculpture by Stephan Balkenhol published. Teddybaer 2025 is a hand-painted bronze sculpture by Stephan Balkenhol from 2025. The human being is at the center of Stephan Balkenhol’s work. He is usually alone, but occasionally he can be accompanied by animals or architectural elements. The figures we encounter in his roughly hewn and painted wooden or bronze sculptures are anonymous, reserved, even emotionless. A man in black trousers and a white shirt is tied to a sphere which, on closer inspection, represents a globe. A distorted image, the imagination? Balkenhol captures unremarkable moments. The people he depicts are completely absorbed in themselves. They appear relaxed, impartial, distanced. Although their gaze is directed at us, it often seems empty. This reinforces their baffling mysteriousness. When Balkenhol studied under Ulrich Rückriem and Sigmar Polke at the Hamburg University of Fine Arts, his figurative compositions ran counter to the prevailing abstract and conceptual art. His works are not portraits in the concrete sense: they do not depict anyone in particular, nor are they signs or symbols of people.

Balkenhol’s use of wood, bronze, and traditional carving methods creates a direct, tactile connection between the viewer and the figure. His style, often described as a return to figurative sculpture in contemporary art, is known for its raw, almost unfinished texture. This rawness adds to the sense of the figure’s humanity. Despite his constrained position, the man remains relatable, imperfect, and very much alive in his quiet endurance.

The sculpture is done of bronze which is alloy of copper with other metals (especially tin) used since ancient times. An ideal metal for high-quality artistic castings that will last for thousands of years. When casting bronze, the artist generally uses a process that is more than 5000 years old, the lost-wax casting process with a lost mold. It is the best, but also the most complex method of producing sculptures. First, the artist forms a model of his sculpture. This is then embedded in a liquefied silicone rubber mass. As soon as the material has solidified, the model is cut out. Liquid wax is poured into the resulting negative mold. After cooling, the wax cast is removed from the mold, provided with casting channels and dipped into a ceramic mass. The ceramic mass is hardened in the kiln and the wax flows out (lost mold).

Now you finally have the negative mold into which the molten bronze at approx. 1400° C is poured. Once the bronze has cooled, the ceramic shell is broken and the sculpture is revealed.

Now the casting channels are removed and the surfaces are polished, patinated and numbered by the artist himself or by a specialist according to his specifications. In this way, each cast becomes an original. For lower quality bronze castings, the sand bed process is often used, but its surface finish and quality cannot match the more elaborate lost wax process.

Balkenhol’s use of wood, bronze, and traditional carving methods creates a direct, tactile connection between the viewer and the figure. His style, often described as a return to figurative sculpture in contemporary art, is known for its raw, almost unfinished texture. This rawness adds to the sense of the figure’s humanity. Despite his constrained position, the man remains relatable, imperfect, and very much alive in his quiet endurance.

The sculpture is done of bronze which is alloy of copper with other metals (especially tin) used since ancient times. An ideal metal for high-quality artistic castings that will last for thousands of years. When casting bronze, the artist generally uses a process that is more than 5000 years old, the lost-wax casting process with a lost mold. It is the best, but also the most complex method of producing sculptures. First, the artist forms a model of his sculpture. This is then embedded in a liquefied silicone rubber mass. As soon as the material has solidified, the model is cut out. Liquid wax is poured into the resulting negative mold. After cooling, the wax cast is removed from the mold, provided with casting channels and dipped into a ceramic mass. The ceramic mass is hardened in the kiln and the wax flows out (lost mold).

Now you finally have the negative mold into which the molten bronze at approx. 1400° C is poured. Once the bronze has cooled, the ceramic shell is broken and the sculpture is revealed.

Now the casting channels are removed and the surfaces are polished, patinated and numbered by the artist himself or by a specialist according to his specifications. In this way, each cast becomes an original. For lower quality bronze castings, the sand bed process is often used, but its surface finish and quality cannot match the more elaborate lost wax process.

Ads

weitere Ausstellungen von FRANK FLUEGEL GALERIE

28.03.2025 - 31.12.2025

Stephan Balkenhol Teddybaer neue Bronze | FRANK FLUEGEL GALERIE

20.03.2025 - 25.09.2025

Andy Warhol Cambells Soup | FRANK FLUEGEL - Ausstellung

22.02.2025 - 30.12.2025

Alex Katz Olivia - Neue Grafikedition 2025 erschienen | FRANK FLUEGEL GALERIE

09.01.2025 - 00.00.0000

Alex Katz Red Tree - Neue Grafikedition 2025 erschienen | FRANK FLUEGEL GALERIE

15.12.2024 - 31.03.2025

Mr. Brainwash - Whimsical Mountains - Kitzbühel